What are the characteristics of Robot joint gear?

Robot joint gears are essential for transmitting power, slowing down rotation, and boosting torque. This allows for smooth, flexible movements and precise control of the robot's joints, making them a key component for efficient and accurate robotic operation.

Advantages

High precision: The tooth shape and pitch error of precision gears are minimal, ensuring accurate transmission ratios and motion control, ideal for high-precision tasks.

High rigidity: Joint gears must endure high loads and frequent movements, necessitating rigidity to minimize deformation and wear, enhancing stability and accuracy in high-load operations.

Lightweight: Using lightweight materials in gear manufacturing reduces the robot's weight, boosting flexibility and battery life.

Wear resistance: Employing wear-resistant materials and high-precision processing ensures gears maintain stable performance over long-term use.

Robot joint gears are the heart of a robot's transmission system. They play a crucial role in determining how well a robot moves and the range of tasks it can perform. As technology advances, we can expect these gears to become more precise, stiffer, and lighter. Additionally, with smarter and more modular designs, robots will become even more adaptable and reliable.

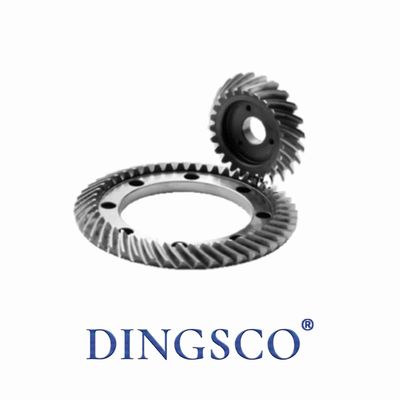

| High-precision wear-resistant spiral bevel gear robot joint gear |

| Specification |

| Material |

Steel |

| Shape |

Spiral |

| Teeth Profile |

Gleason |

| Module (M) |

≤4 |

| Accuracy Grade |

ISO 4-6 Grade |

| Service |

Customized |

| Processing |

Grinding |

| Hardness |

Hardened |

Why choose us?

Since 1994, we have been committed to manufacturing high-quality internal bevel and custom gears. With over 30 years of experience, we adhere to strict ISO 4-6 standards. Quality is our top priority, and each gear is meticulously crafted for reliability and durability. We are confident that our customized, high-quality solutions will exceed your expectations and perfectly meet your needs.

Our team includes a doctoral-degree holder, a respected member of the China Gear Standardization Technical Committee, and a graduate student specializing in bevel gear research.

We take pride in our advanced CNC seven-axis, five-linkage spiral bevel gear grinding and milling machines in our factory. We also possess a full suite of cutting-edge production and testing equipment to ensure every product meets the highest standards of quality and efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!